3D printing technology has revolutionized many fields, from industry to art, and has firmly established itself in our lives. However, we must also consider the environmental impact of this technology. Fortunately, the production of filament from recycled materials is gaining increasing attention. One of these innovative steps is the production of filament from PET bottles (Polyethylene Terephthalate – PET). This solution, both environmentally conscious and low-cost, has generated significant interest in the 3D printing world. In this blog post, we will delve into the processes, benefits, and characteristics of producing 3D filament from PET bottles.

Producing 3D Filament from PET Bottles: Process, Benefits, and Characteristics

How is Filament Produced from PET Bottles?

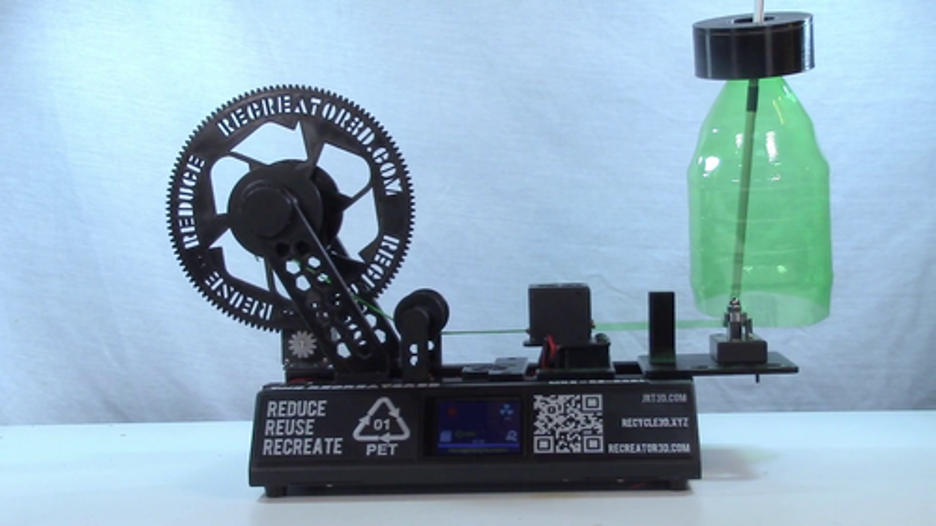

Plastic bottles have become an indispensable part of our daily lives. However, when not properly recycled, these bottles contribute significantly to environmental pollution. In the PET bottle recycling process, collected PET bottles are first cleaned and then shredded into granules. These granules are then melted down in specialized equipment, such as a filament recycling machine, to be extruded into PET filament.

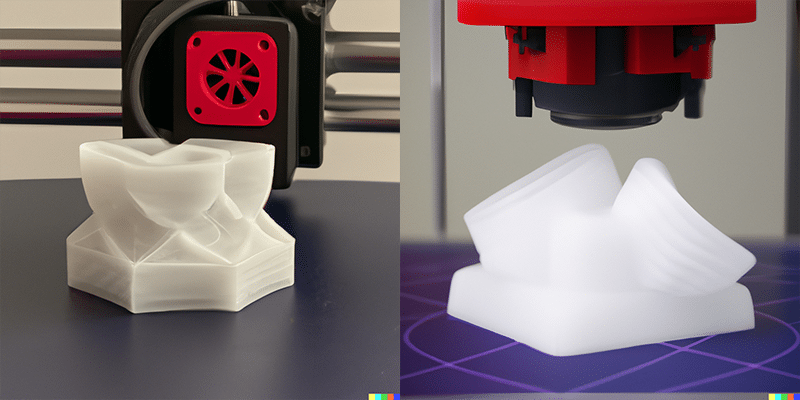

The recycled plastics used in filament production exhibit properties similar to original PET filaments. Flexibility, durability, and a smooth surface are maintained, while providing an environmentally friendly solution.

Benefits of Recycling: Environmental and Economic Impacts

The greatest advantage of 3D printing filaments produced from PET bottles lies in their environmental benefits. Billions of plastic bottles are produced globally each year, and unfortunately, a large portion ends up in landfills or nature without being recycled. Transforming PET bottles into new and useful products like 3D printing filament helps prevent the accumulation of this plastic waste in the environment.

Furthermore, these recycled PET filaments help reduce virgin plastic consumption, lower the carbon footprint, and minimize the depletion of natural resources. Moreover, individuals and companies that produce using this filament contribute to a sustainable future by choosing environmentally conscious solutions.

The characteristics of recycled PET filaments are generally quite similar to virgin PET filaments. PET is a lightweight, durable, and highly flexible material, making it ideal for various applications. Recycled PET filaments, on the other hand, offer both a cost advantage and stand out as an environmentally friendly option.

These filaments are particularly suitable for prototyping, artistic works, decorative objects, and low-stress mechanical parts. However, they may not meet specific standards for food contact, so they should be used with caution in such applications.

Challenges and Areas for Development

Although filaments produced from PET bottles are highly promising, the process does present some challenges. Recycled PET filaments may not always be as homogeneous and stable as virgin materials, which can lead to fluctuations in print quality. Additionally, the purity and quality of the plastics used in the recycling process can affectthe performance of the final filament.

These challenges can be overcome with continuous technological advancements. Researchers and engineers are constantly working to improve the properties of recycled materials and expand their application areas. Developments in filament recycling machine technologies, in particular, are enhancing the efficiency of this process.

An Important Step Towards a Sustainable Future

With the rapid spread of 3D printing technology, the sustainable use of material resources is becoming increasingly important. Filaments produced from PET bottles emerge as an innovative solution offering significant environmental and economic advantages. This combination of recycling and 3D printing prevents plastic waste from harming the environment by bringing it back into reuse.

In conclusion, filaments produced from PET bottles can be considered a revolutionary step in the 3D printing world, ushering in a new era in recycling. In a future where sustainable production and consumption habits are adopted, such innovative solutions will continue to be of great importance for a more livable world.