Flexible, Fast and Economical 3D Printing Service in Istanbul Kadıköy

We offer flexible, economical and complex geometry 3D printing solutions with CAD-supported layered production methods in Istanbul.

Fast and Economical 3D Printing Solutions in Kadıköy

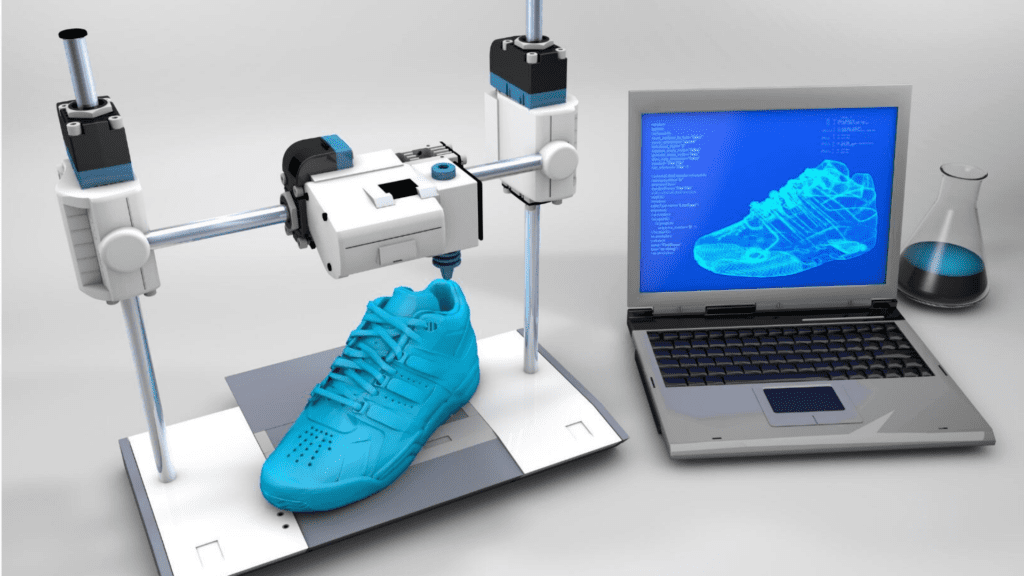

3D printing is a revolutionary manufacturing technology that enables digital designs to be transformed into real-world objects. This technology allows digital models created with computer-aided design (CAD) software to be physically produced layer by layer using a material. In many sectors, 3D printing enables prototypes to be produced quickly and cost-effectively, while also revolutionizing areas such as customized manufacturing, spare part production, and low-volume mass production.

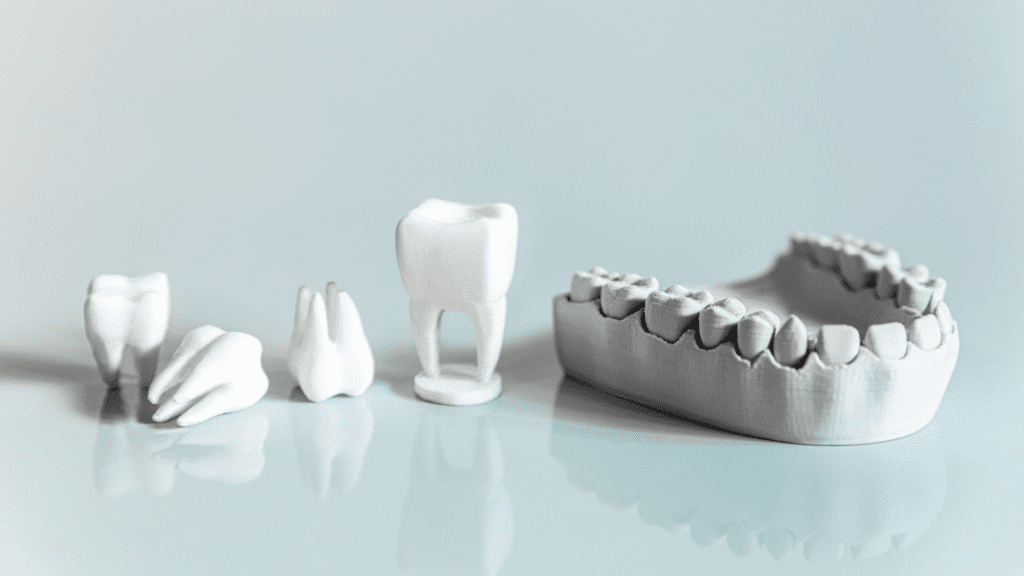

Compared to traditional manufacturing methods, 3D printing facilitates the printing of complex internal structures, organic forms, and fine details that require control. It revolutionizes patient care processes, especially in the medical field, by producing pre-operative models, preparing dental molds for dental applications, and recreating biological tissues.

Our Kadıköy 3D printing service offers flexible options covering different printing technologies such as FDM, SLA, and SLS. Thanks to the industrial-type printers that you can reach at any time from our office in Kadıköy, one of the central districts of Istanbul, you can meet your prototyping needs in your field work or in-office without additional investment.

Advantages of 3D Printing Services

Our 3D printing services significantly accelerate prototyping processes by keeping the transition time from 3D design to physical model between 24-48 hours on average. For example, an industrial equipment manufacturer shortened its product development cycle by 60% by having the first 3D drawing file delivered via CAD within 36 hours. This minimized the waiting times between field tests and design revisions.

We offer economical solutions without the need for mold and molding costs in low-volume production. Our FDM and SLA printing options, which provide up to 50% cost advantage compared to CNC machines in small series of 50-200 pieces, protect your budget with intuitive pricing models. Functional prototypes produced with metal powder printing reduce test costs by 40% in test processes in the aerospace and automotive sectors.

Our wide range of materials such as PLA, ABS, photopolymer resins, PA12 and metal alloys meet different performance requirements such as high temperature resistance, chemical resistance and mechanical strength. Thanks to our filament options with different features, we allow you to produce both lightweight and impact-resistant parts with our carbon fiber filament reinforced and flexible TPU materials. In addition, thanks to our lattice designs with optimized internal structures and topology optimization support, you can both reduce part weight and increase mechanical strength. With this flexible, economical and fast service package, we offer an ideal 3D printing partner for all individual designers and corporate R&D teams in Istanbul. Get a quote!

Frequently Asked Questions (FAQ)

How long does it take to prepare a 3D printing order?

Depending on the project and the technology chosen; simple prototypes are usually completed within 24–48 hours, while complex and large parts are completed within 2–4 business days.

How is pricing done in 3D printing?

Price is calculated according to part volume (volume-based pricing), material selection (PLA, ABS, resin, PA12, metal powders, etc.) and printing time. Our rental fees are offered in daily, weekly and monthly flexible packages; we offer a free quote if you send us your project details.

What methods can 3D printing be done with?

We support a wide range of materials such as PLA, ABS, PETG, TPU (flexible), photopolymer resins (SLA/DLP), PA12 (SLS), metal alloys (MJF/SLM) and carbon fiber reinforced versions. We provide consultancy on the mechanical, thermal and surface properties of each material.

What processes can be done after 3D printing?

We have polishing, painting, assembly, support material cleaning and surface roughness improvement processes. We also offer lattice internal structure optimization, topology optimization and assembly services.

How to get a quote for 3D Printing?

You can request a free survey and quote by filling out the short form on our website or sharing your project details on our WhatsApp line. Our technical team will get back to you within 2 business hours.

How is large-volume or industrial part 3D scanning done?

Yes, we integrate both “3D Large Product Scanning” and 3D printing solutions.

We can scan meter-long parts such as ship hulls, wind-turbine blades and pipelines using laser and photogrammetry, then apply direct printing or reverse-engineering workflows to the captured data.