3D technical design is an innovative technology that enables the modeling, design, and optimization of production processes for three-dimensional (3D) objects and products in a digital environment. Along with evolving digitalization and engineering techniques, this technology has revolutionized every sector of industry, playing a significant role particularly in product development, prototyping, architecture, automotive, and industrial design. At the heart of this process lie the principles of traditional technical drawing orthographic projection and view extraction.

Three-dimensional technical design expands the boundaries in visual communication, design, and production, becoming one of the fundamental building blocks of the digital world. In this blog post, we will delve into what 3D technical design is, how it’s done, its advantages, and its future role, including examples of orthographic projection in technical drawing. We’ll also touch upon resources like technical drawing examples, various technical drawing views, and technical drawing book PDFs.

A Comprehensive Guide to Technical Drawing Orthographic Projection and 3D Technical Design

What is 3D Technical Design?

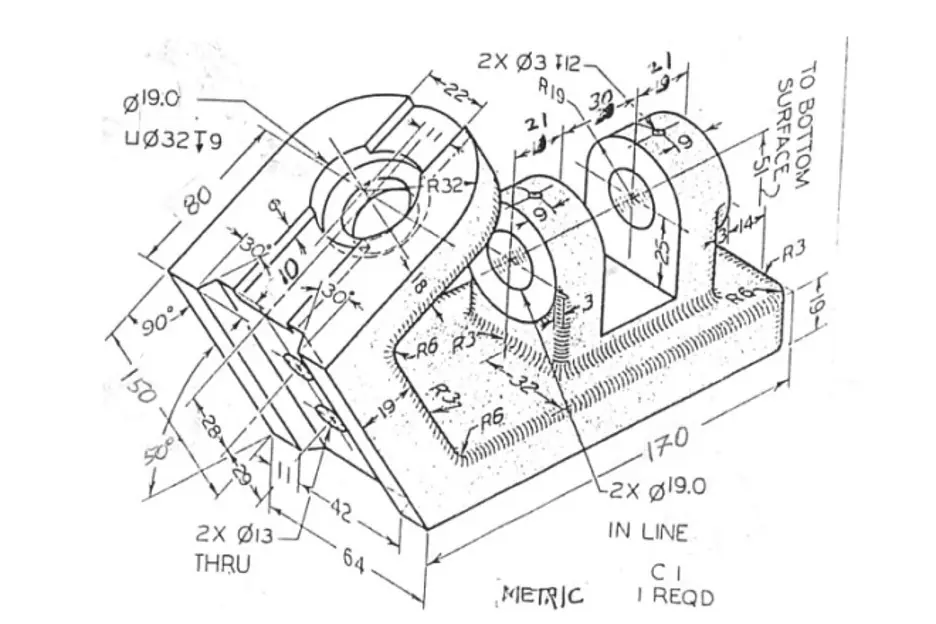

3D technical design is the process of creating three-dimensional models using computer-aided design (CAD) software. In this process, designers and engineers can digitally model objects according to their real-world measurements and dimensions. CAD software allows for detailed creation of complex product designs, performing simulations, and preparing these designs for production. It’s a more functional and interactive digital evolution of traditional technical drawing examples. This enables easy creation of different technical drawing views of products in a digital environment.

3D Design Process and Technical Drawing Principles: Step-by-Step

Concept Development

The 3D design process begins with conceptualizing a product or structure. At this stage, fundamental design ideas are developed, considering customer requirements, aesthetics, and functional characteristics.

Modeling and Orthographic Projection

3D models are created using CAD software. This stage involves converting two-dimensional designs and technical drawings into 3D digital models. Designers establish the object’s geometric structure, defining dimensions and material properties. During this process, various technical drawing views of the product are obtained, and detailed orthographic projection (view extraction) operations are performed. If necessary, sectioning techniques are also applied to show internal details.

Simulation and Analysis

3D models undergo simulations to test the engineering durability and performance of the design. This step, particularly used in automotive, aerospace, and industrial design, helps predict how the product will perform in the physical world.

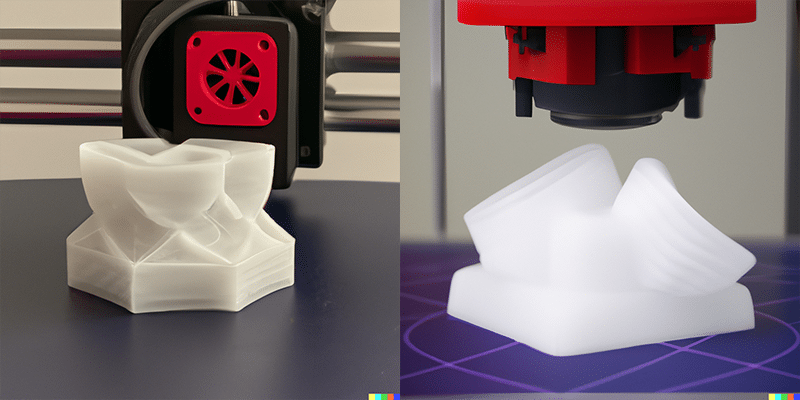

Prototype Production

After the modeling and simulation stages, a physical prototype of the design is typically produced using 3D printing or CNC machines. This stage offers the opportunity to test how the design will take form and function in the real world.

Final Production

The final version of the product is determined after all analyses and improvements. Thanks to the high precision provided by 3D technical design, the final production stage becomes faster and more efficient.

Advantages of 3D Technical Design

3D technical design offers many advantages over traditional two-dimensional design processes. Here are some of them:

- High Precision and Detailed Modeling: 3D design tools allow for accurate modeling of complex geometries and details. This provides a significant advantage, especially in precise engineering projects and product designs. Far more detailed and error-free models can be created compared to traditional technical drawing examples.

- Rapid Prototype Creation: With 3D printing and rapid prototyping technologies, digital models can be quickly transformed into physical objects. This accelerates the product development process and allows for testing the design in pre-production phases.

- Simulation and Testing Capabilities: Simulations performed on 3D models offer the opportunity to evaluate how a product will perform before a physical prototype is created. This saves time and cost and provides important feedback for product improvement.

- Cost Savings: Compared to traditional manufacturing methods, 3D technical design processes result in less material waste and prevent unnecessary costs by detecting design errors early.

- Flexibility: 3D technical design processes allow for quick changes in design and immediate visualization of these changes. This flexibility optimizes designers’ and engineers’ creative processes and enables quick responses to customer feedback.

Industries Where It Is Used

3D technical design is widely used in many different industries. Here are some of the main sectors where this technology is commonly applied:

- Automotive: 3D technical design plays a critical role in the design and prototyping of vehicle parts and components. Engineers use this technology for aerodynamic structures and durability tests.

- Architecture and Construction: Digital modeling of buildings and large structures ensures a more efficient construction process and optimizes aesthetic and functional design processes.

- Medicine: 3D technical design is of great importance, especially in the personalized design of orthopedic implants, prosthetics, and medical devices. Medical solutions tailored to individuals’ body structures can be produced faster and more accurately with these technologies.

- Industrial Design: In the design of machine parts, electronic devices, and other industrial products, 3D technical design processes are crucial for both functionality and aesthetics.

The Future of 3D Technical Design

3D technical design technology continues to evolve, expanding into broader areas with innovations. 3D design processes integrated with artificial intelligence and machine learning offer more autonomous and efficient design models, while enabling the development of more sustainable solutions through material science and new production techniques.

The importance of this technology will continue to grow, particularly in personalized product design and manufacturing processes. Along with comprehensive data analysis and flexible design processes tailored to user demands, 3D technical design will continue to be one of the most important engineering and design tools of the future. For those looking to develop themselves in this field, resources like technical drawing book PDF and examples of orthographic projection in technical drawing will be indispensable for foundational knowledge.

Conclusion: The Future of Engineering and Production

3D technical design is an innovative technology with great potential in both engineering and creative sectors. With advantages like high accuracy, rapid prototyping, and cost savings, it is replacing traditional design processes and enabling more sustainable, flexible production methods. This technology, evolving with the growing needs of industries, will continue to play a key role in future product development processes. The skill of technical drawing orthographic projection remains a fundamental competency in this digital transformation.