FDM Technologoy

Increase Your Productivity with 3D Printing

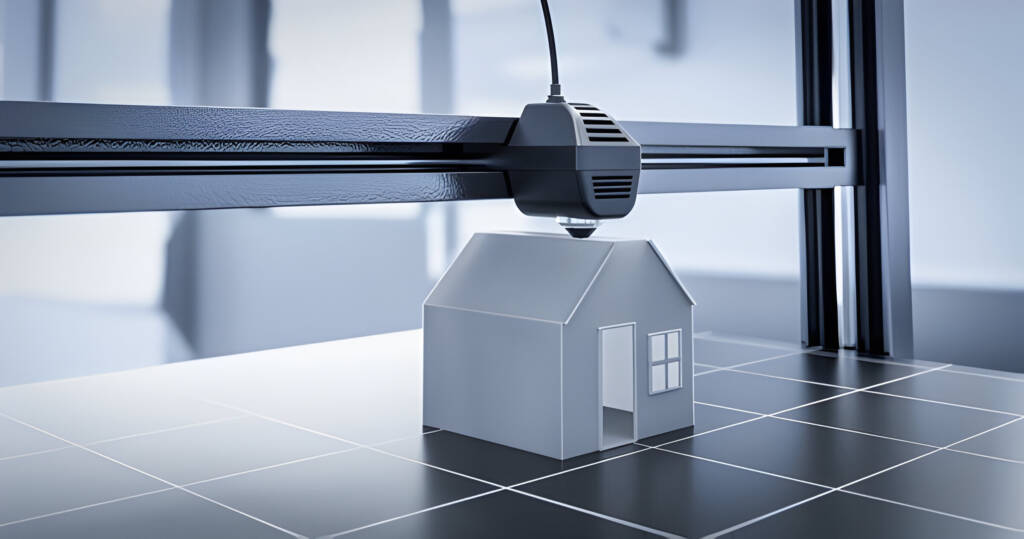

In the world of 3D printing, FDM (Fused Deposition Modeling) is a technology that has created a major revolution. This technology allows the creation of three-dimensional objects by melting and layering plastic or similar materials. At MARM Engineering, we offer our expertise and experience in FDM technology to you.

What is FDM Technology?

FDM is a method used to create a sample or prototype in the 3D printing process. In this process, thermoplastic materials are melted with a nozzle and then added in layers to a surface. Each layer solidifies on top of the previous layer, eventually forming the desired object. FDM is a unique solution for rapid prototyping, customization, and production.

Advantages of FDM Technology

Cost Efficiency

Rapid Prototyping

Customization

Ease of Use

FDM Material List

High mechanical strength and strong interlayer adhesion, organic-based material.

High mechanical strength and strong interlayer adhesion, organic-based material.

A material commonly preferred for impact resistance and high-temperature resistance.

A material with high chemical resistance and high tensile strength with Shore 90A hardness.

It has high strength, hardness, and bending resistance.

A polymer that can withstand temperatures up to 150°C and achieve almost metal-like strength.

Resistant to outdoor conditions, with high chemical resistance and heat resistance.

A material compatible with food, providing leak-proofing and strong interlayer adhesion.

A material with high strength used in functional part production and engineering applications.

In addition to flame retardancy, it has high hardness and impact resistance.

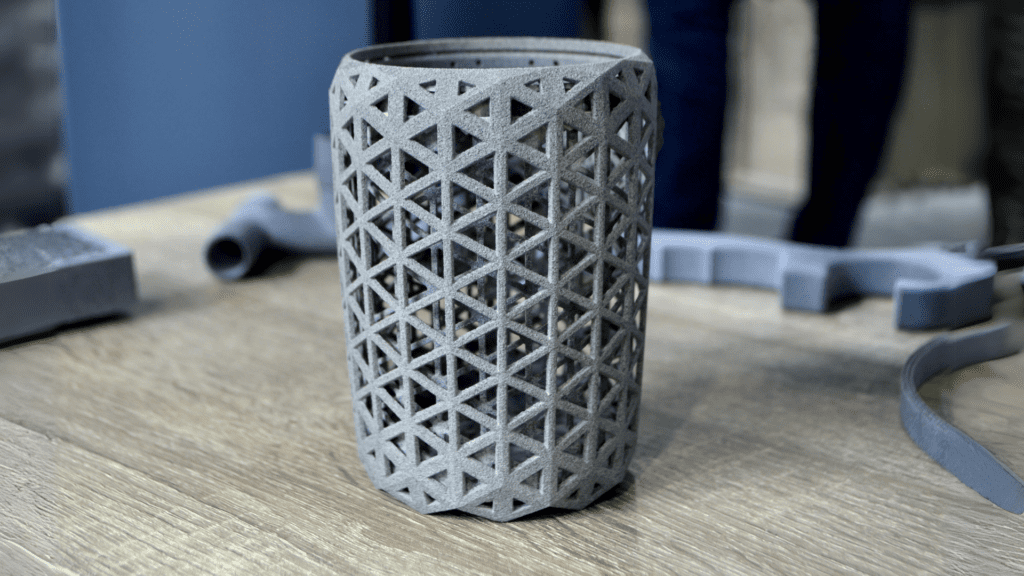

FDM (Fused Deposition Modeling) technology is a widely used 3D printing method that creates 3D objects by layering thermoplastic materials. The possibilities with this technology are generally as follows:

- Product Development: FDM enables rapid prototyping of designs, allowing ideas to be quickly tested and refined.

- Small-Scale Production: It offers a cost-effective solution for custom parts or low-volume production needs.

- Educational Use: Provides students and researchers with the opportunity to visualize engineering and design processes, enhancing learning.

- Art and Design Applications: Used in creative sectors to create complex geometric shapes and unique designs.

- Personalized Products: Offers flexibility in the production of custom, personalized products.

- Functional Testing: Produced parts can be tested in real-world conditions to evaluate functionality and durability.

- Spare Parts Production: Ideal for the reproduction and quick availability of especially old or hard-to-find parts.